types of cnc machine pdf

This is a small grinder operated with electric power. Grinding can be done by holding it in hand.

Cnc Milling A Complete Guide To Understand The Process

The real advantage is that it can be used to create features in the sides of vacuum forming eg.

. It does not eliminate the need for costly tools. Machining is a very precise method of creating holes features. Based on different systems there will be subtle differences.

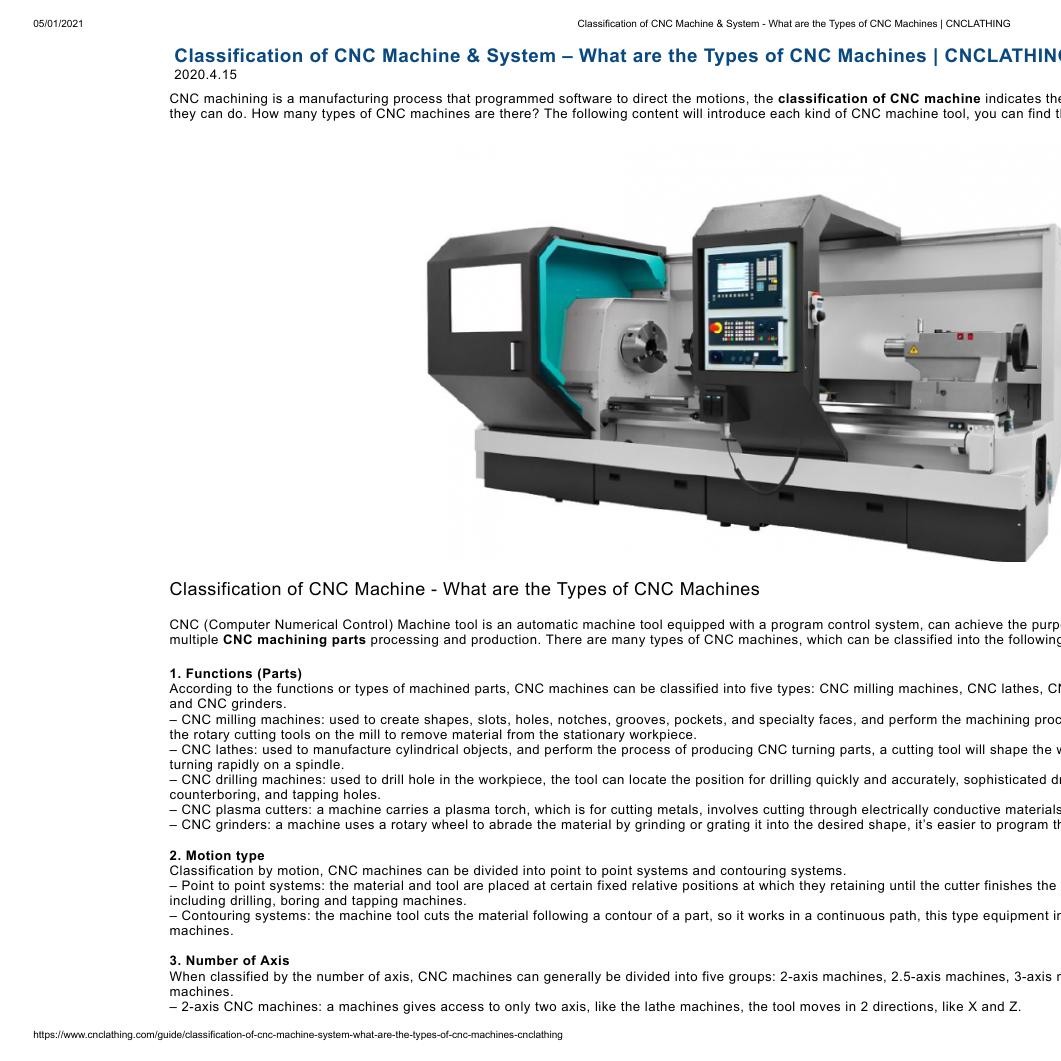

The initial cost is high. Numerical control also computer numerical control and commonly called CNC is the automated control of machining tools such as drills lathes mills grinders routers and 3D printers by means of a computerA CNC machine processes a piece of material metal plastic wood ceramic or composite to meet specifications by following coded programmed. Lathe Machines are used in metalworking woodturning metal spinning thermal spraying glass working and parts reclamation.

The development of Computer Numeric Controlled Machines for example has made us able to mass-produce and reproduce products faster with less waste and often more complex in design than ever beforeCNC wood routers can carve complicated and highly detailed shapes. As we know machines like lathe Milling and Drilling operations are performed manually and there is more involvement of humans to perform and time taking is high average precision and accuracySo to overcome this problem the machine manufactured is CNC which is known as Computer Numerically controlled. This machine is used to produce gears like spur gear and is also.

Machine shop notespdf 1. Following are the disadvantages of CNC Machine. It can also cut.

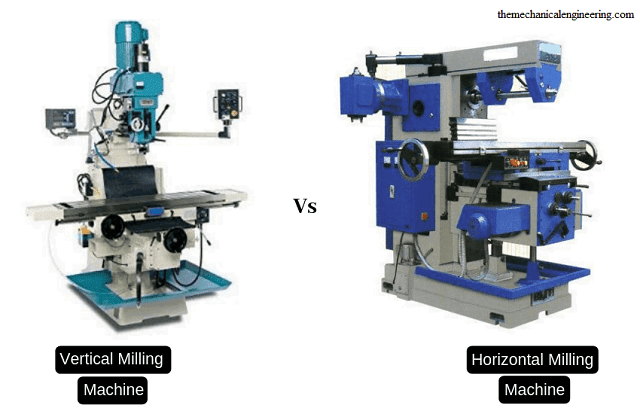

Our series of manual mill machines include your vertical horizontal verticalhorizontal combined spindles. Shop by department purchase cars fashion apparel collectibles sporting goods cameras baby items and everything else on eBay the worlds online marketplace. This is a list of file formats used by computers organized by type.

In the industrial design field of humancomputer interaction a user interface UI is the space where interactions between humans and machines occurThe goal of this interaction is to allow effective operation and control of the machine from the human end while the machine simultaneously feeds back information that aids the operators decision-making process. The various other operations that you can perform with the help of a Lathe Machine can include sanding. Due to the different styles of G-code its necessary to understand how your own machine uses G-code.

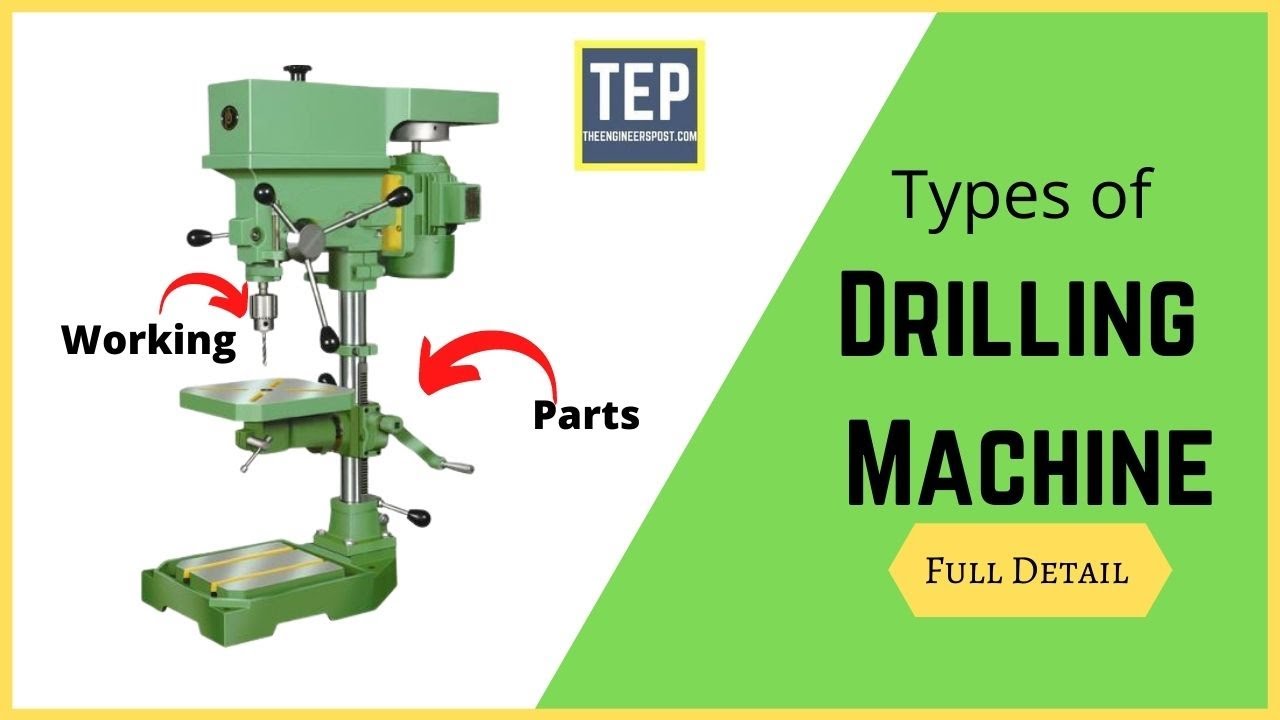

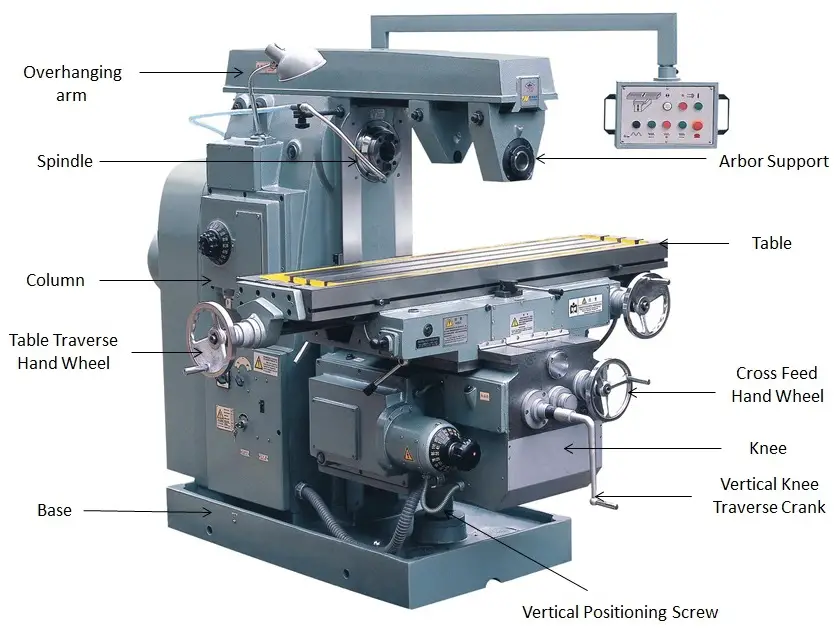

It is one of the most common types of CNC machine that have built-in tools for drilling and cutting. Milling is the process of machining using rotary cutters to remove material by advancing a cutter into a workpieceThis may be done by varying direction on one or several axes cutter head speed and pressure. Working principle of Grinding Machine.

Computer Numeric Control lathe CNC lathe 153 Principal parts of an engine lathe 23. On one end of the motor shaft a grinding wheel is fitted and on the other end a handle or switch for operating the machine is fixed according to our convenience. Also Haas and Fanuc G-Code M-Code PDF files are provided for download.

Some variations are not all that obvious and others are more a niche area. The model with 2 spindles can do 5 sided machining with the optional rotary table or indexer. A lathe machine is a machine tool that is used to remove metals from a workpiece to give a desired shape and size.

A robot can be guided by an external control device or the control may be embedded within. A lathe machine is a machine that holds the workpiece on a chuck and tool on a toolpost the lathe machine rotates the workpiece about an axis to perform different operations such as turning facing chamfering thread cutting knurling drilling and more with tools that are applied to the workpiece to design an object with symmetry about that axis. Filename extension it is usually noted in parentheses if they differ from the file format name or abbreviation.

Advanced CNC press brake mainly adopts hydro-electric servo system and grating ruler to form closed-loop. There are many variants of lathes within the metalworking field. A robot is a machineespecially one programmable by a computercapable of carrying out a complex series of actions automatically.

The cost of a CNC machine is much higher than a manually operated machine. Blums Process 32 Manual PDF October 15 2003. The processes that have this common theme are collectively called subtractive manufacturing which utilizes machine tools in contrast to additive manufacturing 3D printing which uses controlled addition of material.

All machine tools have some means of constraining the work piece and provide a guided movement of the parts of the machine. For example a centering lathe is a dual head machine where the work remains fixed and the heads move towards the workpiece and machine a center drill hole into each end. Machining is a process in which a material often metal is cut to a desired final shape and size by a controlled material-removal process.

The working principle of a grinding machine is quite easier to understand. Maintenance costs are significantly higher in the case of CNC. Here you can check out the list of Haas G Codes and Haas M Codes for CNC LathesMills.

In a grinding machine there is an electric motor which supplies the motion power to the grinding wheel with the help of a belt and pulley. Lets understand in detail also at the end of the article I will. MACHINE SHOP PRACTICE S5 MECH 2015 22 1.

CNC machine requires skilled programmers. With the advances in modern technology and the demands of industry woodwork as a field has changed. This is an economical and simple CNC bed type mill for machining large work piece.

Robots may be constructed to evoke human form but most robots are task-performing machines designed with an emphasis on stark functionality rather. CNC Metal Cutting Machine Tools market is valued at 78070 million USD in 2020 is expected to reach 147330 million USD by the end of 2026 growing at a CAGR of 94 during 2021-2026. Overview Features Basic Elements Working.

Many operating systems do not limit filenames to one extension shorter than 4 characters as was common with some operating systems that supported the File Allocation Table FAT file system. Types of molds There are numerous patterns one can make with vacuum forming. So when we start the electric motor the motor rotates at a certain rpm 150-15000 RPM it may change according to the types of.

Most of the CNC milling machines are available in 3 to 6-axis configurations. He completed his engineering studies in 2014 and is currently working in a large firm as. Milling covers a wide variety of different operations and machines on scales from small individual parts to large heavy-duty gang milling operations.

The materials are located inside a milling CNC machine after which the computer will lead the tools to drill or cut them. Is a Mechanical Engineer by profession. The parts of the CNC machines are costly.

A machine tool is a machine for handling or machining metal or other rigid materials usually by cutting boring grinding shearing or other forms of deformationsMachine tools employ some sort of tool that does the cutting or shaping. Cutting with a CNC machine. When using a CNC press brake you only need to input the number of the pieces required for bending as well as the bending angle for each step the CNC press brake will finish bending according to the steps you just set in the controller.

Free press release distribution service from Pressbox as well as providing professional copywriting services to targeted audiences globally. The bed is a heavy rugged casting and it carries the headstock and tailstock for supporting the work piece and provides a base for the movement of carriage assembly which carries. Types of metal lathes.

It can be easily carried anywhere. The resulting workpiece may then be. Guide rails for a tray that needs to slide onto shelving.

Parts Working and Types of Rolling Mills with PDF 13 Main Difference between NC CNC and DNC Machine. It is used for cleaning heavy welding jobs.

Cnc Machine Types Of Cnc Machine Parts Application And Specifications Pdf Riansclub

Difference Between Horizontal And Vertical Milling Machine Notes Pdf

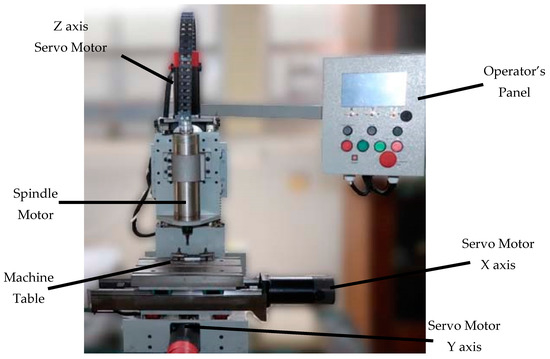

What Is The Working Principle Of A Cnc And Types Of Cnc Controllers

Cnc Machining What Is It How Does It Work Types Codes

Pdf Intelligent Optimal Tool Selections For Cnc Programming Of Machine Tools

Cnc Machine Definition Types Components Working Function Applications Advantages And Disadvantages Pdf

Pdf Major Cnc Machine Tool Types Alphonce Kibet Academia Edu

Machining Technology Lab Manual Mechanical Manufacturing Technology 2

Applied Sciences Free Full Text Step Nc Compliant Intelligent Cnc Milling Machine With An Open Architecture Controller Html

What Is Milling Parts Operations And Types Of Milling Machine Youtube

Types Of Cnc Machine Explained In Detail Lathe Laser Plasma And More Youtube

Seal System Made In U S A Mso Industries

What Is Cnc Machining 3 Axis 4 Axis 5 Axis

Classification Of Cnc Machine System What Are The Types Of Cnc Machines Cnclathing Pdf Docdroid

Cnc Machining Handbook Building Programming And Implementation Overby Alan 8601417898581 Amazon Com Books

Cnc Milling A Complete Guide To Understand The Process

What Is Milling Machine Operation Parts And Types Mechanical Booster